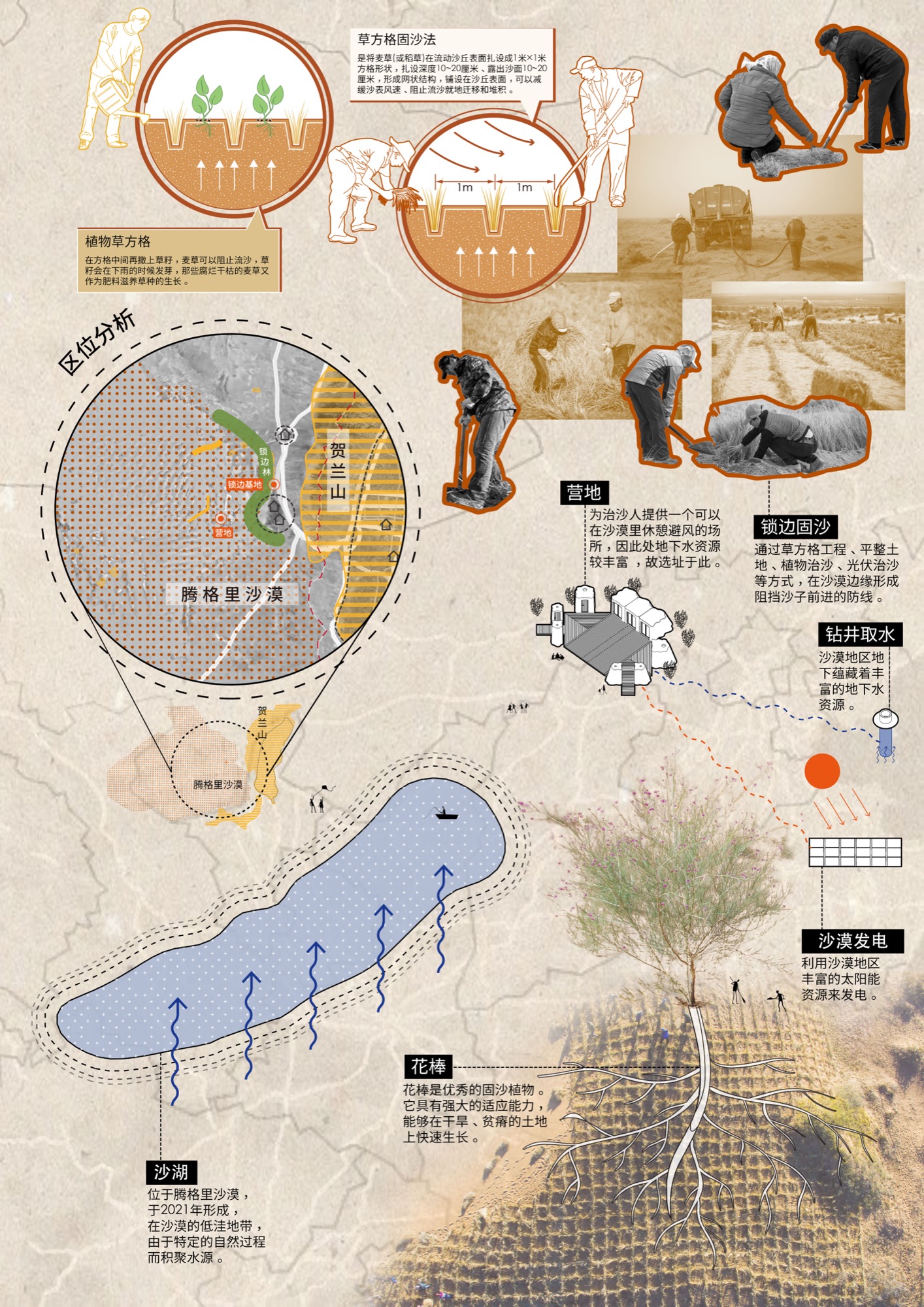

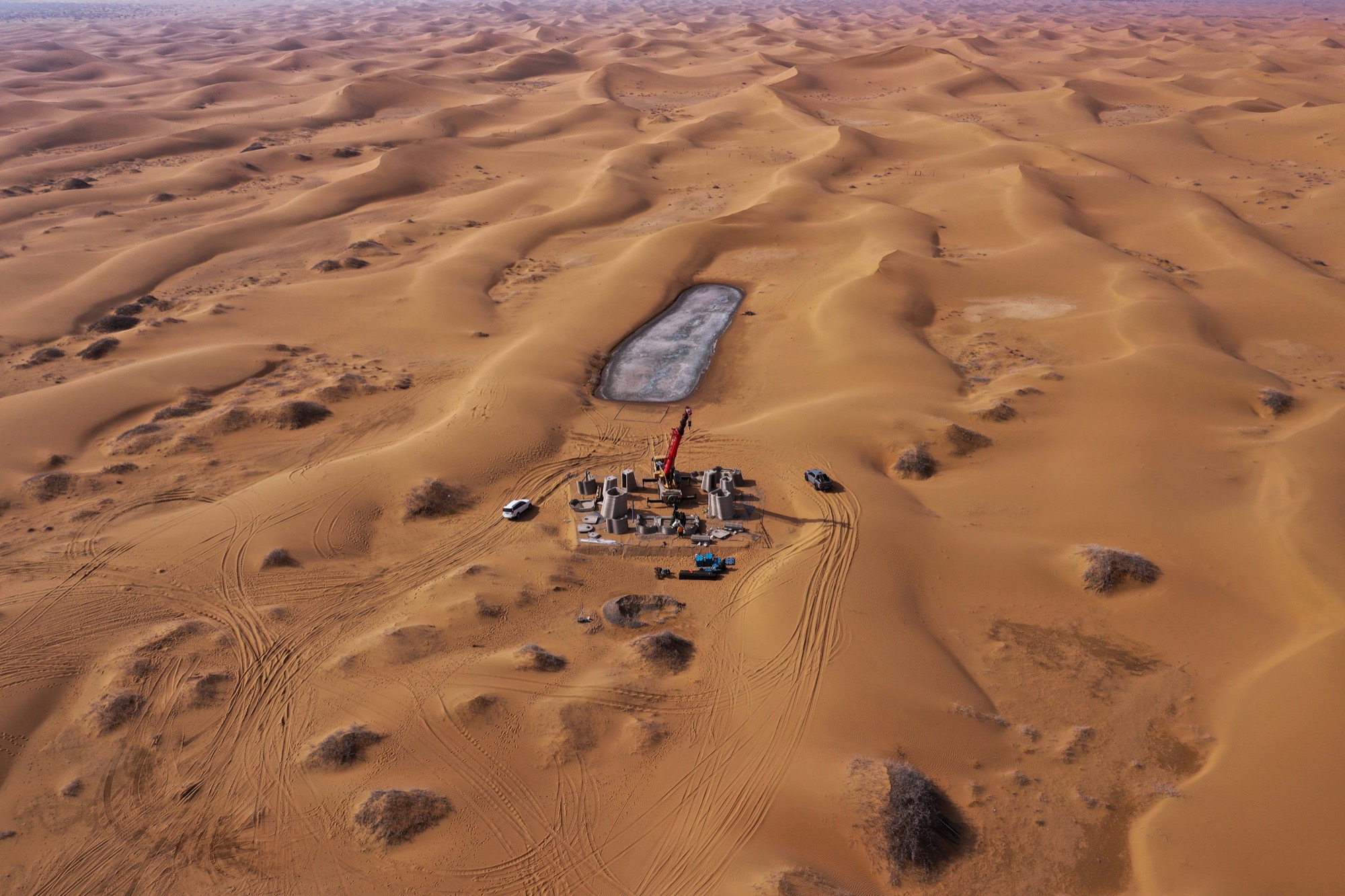

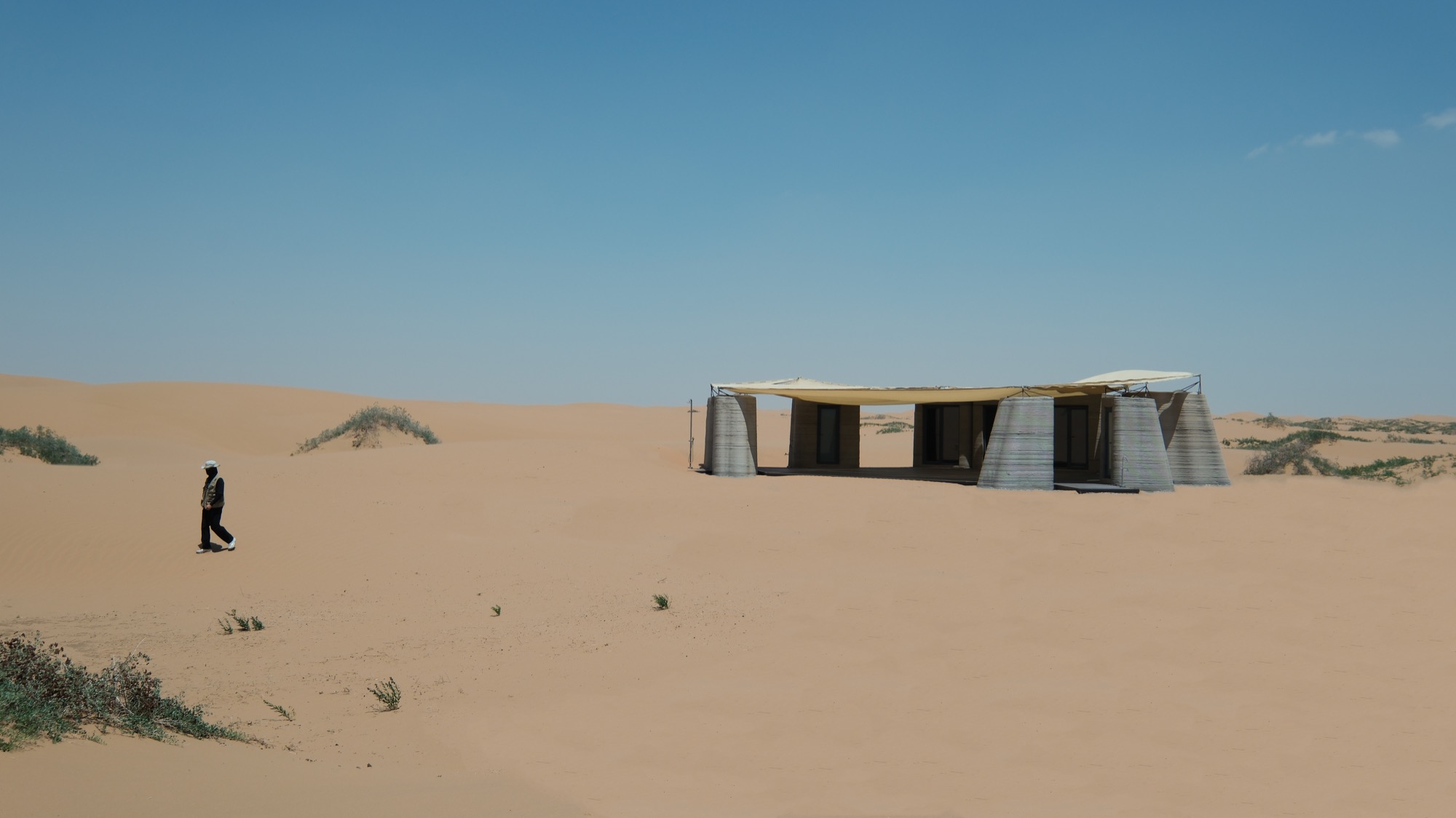

The Tengger Desert, once the source of sandstorms that threatened all of East Asia, is being reclaimed by expanding green belts planted since the early 1990s. Amid this harsh terrain, designRESERVE constructed the Desert Noah Ark – China’s first 3D-printed concrete structure built in an extreme natural environment. It serves both as a shelter for forest rangers and volunteers, and as a prototype for human habitation in future extra-terrestrial or hostile landscapes.

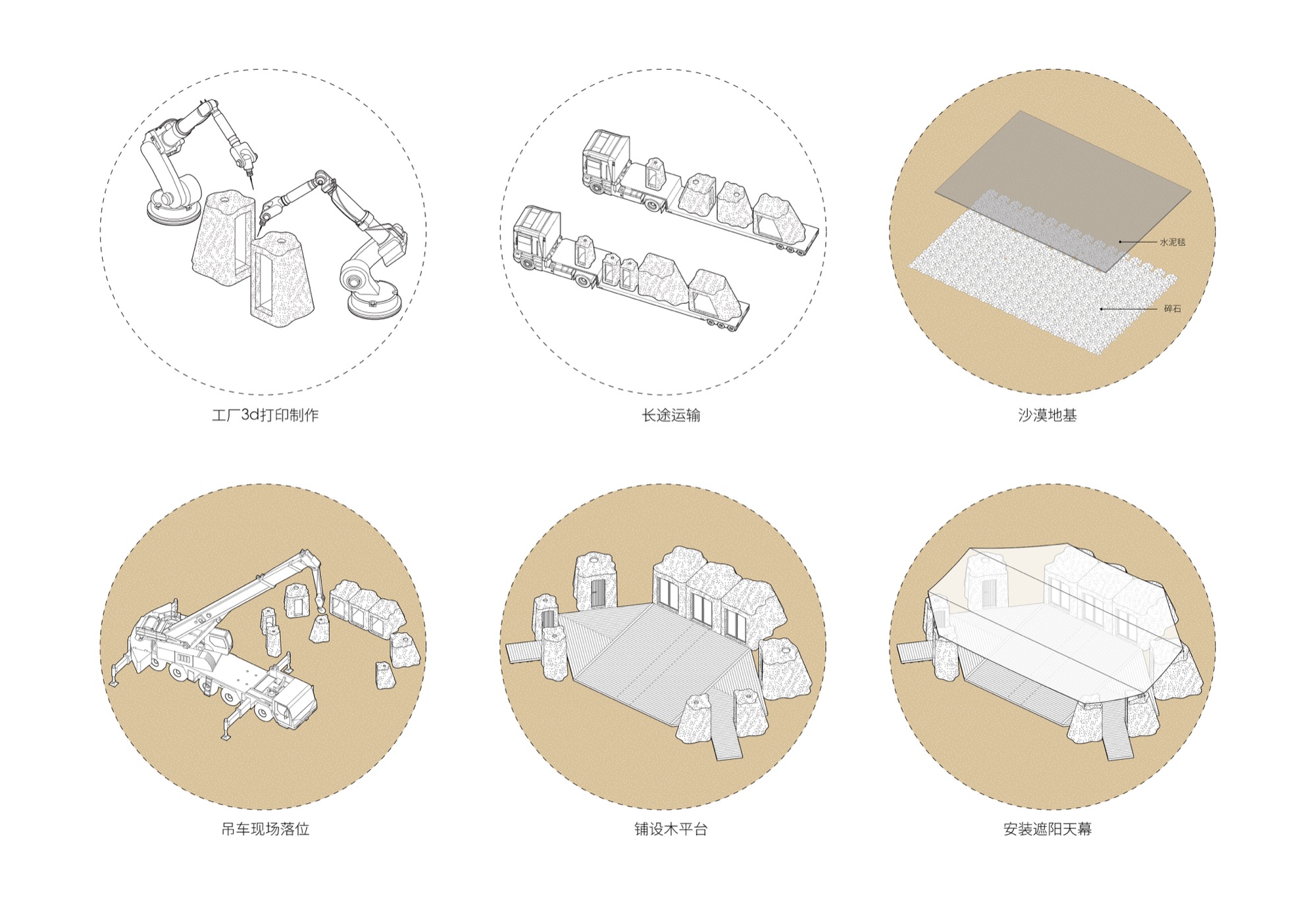

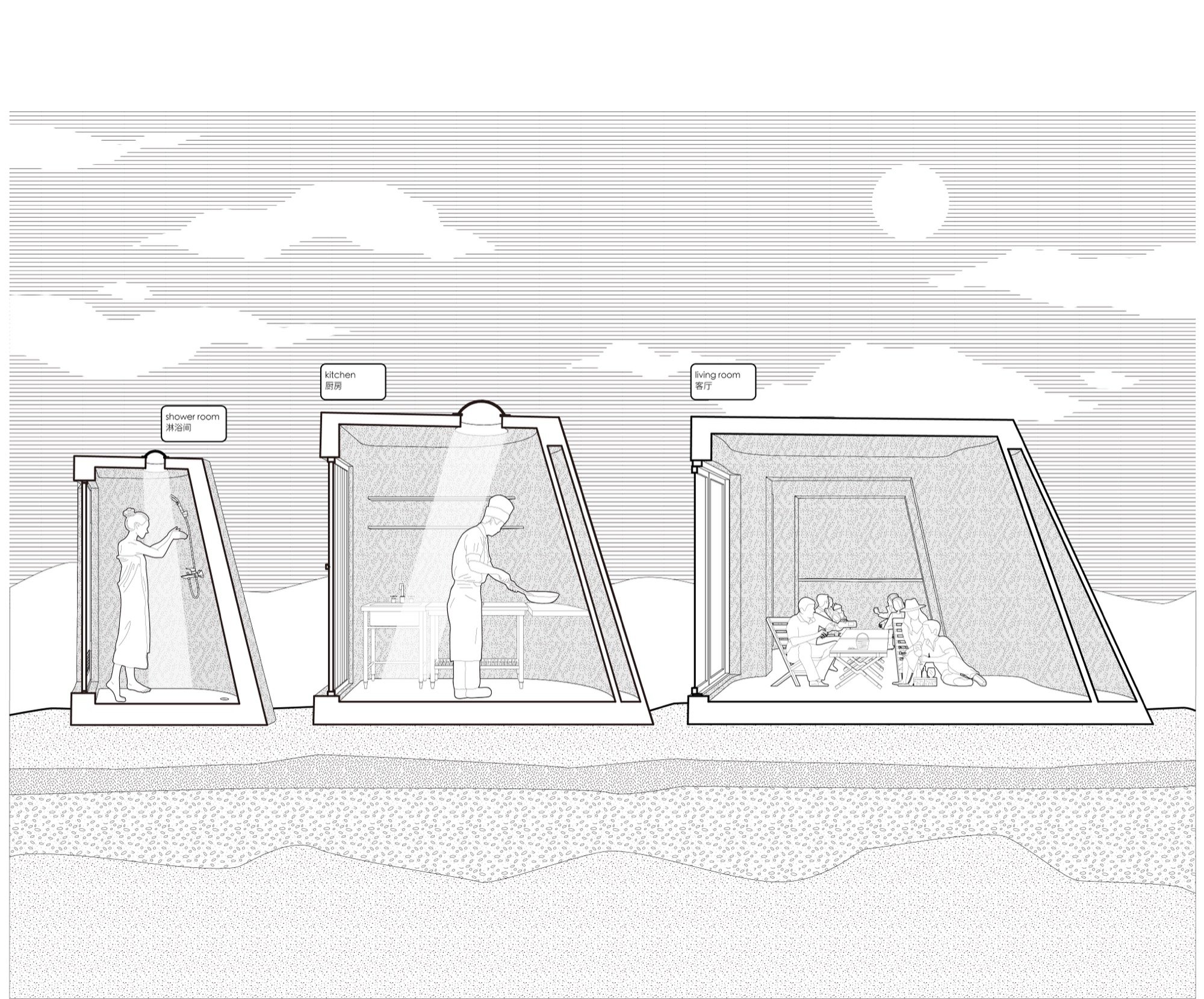

Initiated by the non-profit organization Planting Trust, the project is located in Alxa Left Banner, Inner Mongolia, where winds reach 34 meters per second, daytime temperatures rise to 45°C, and nights plunge below -30°C. Working with limited funds and time, the team adopted 3D-printed concrete technology developed by Professor Xu Weiguo’s lab at Tsinghua University. The 150-square-meter compound is divided into nine modular units containing living, cooking, bathing, and storage spaces.

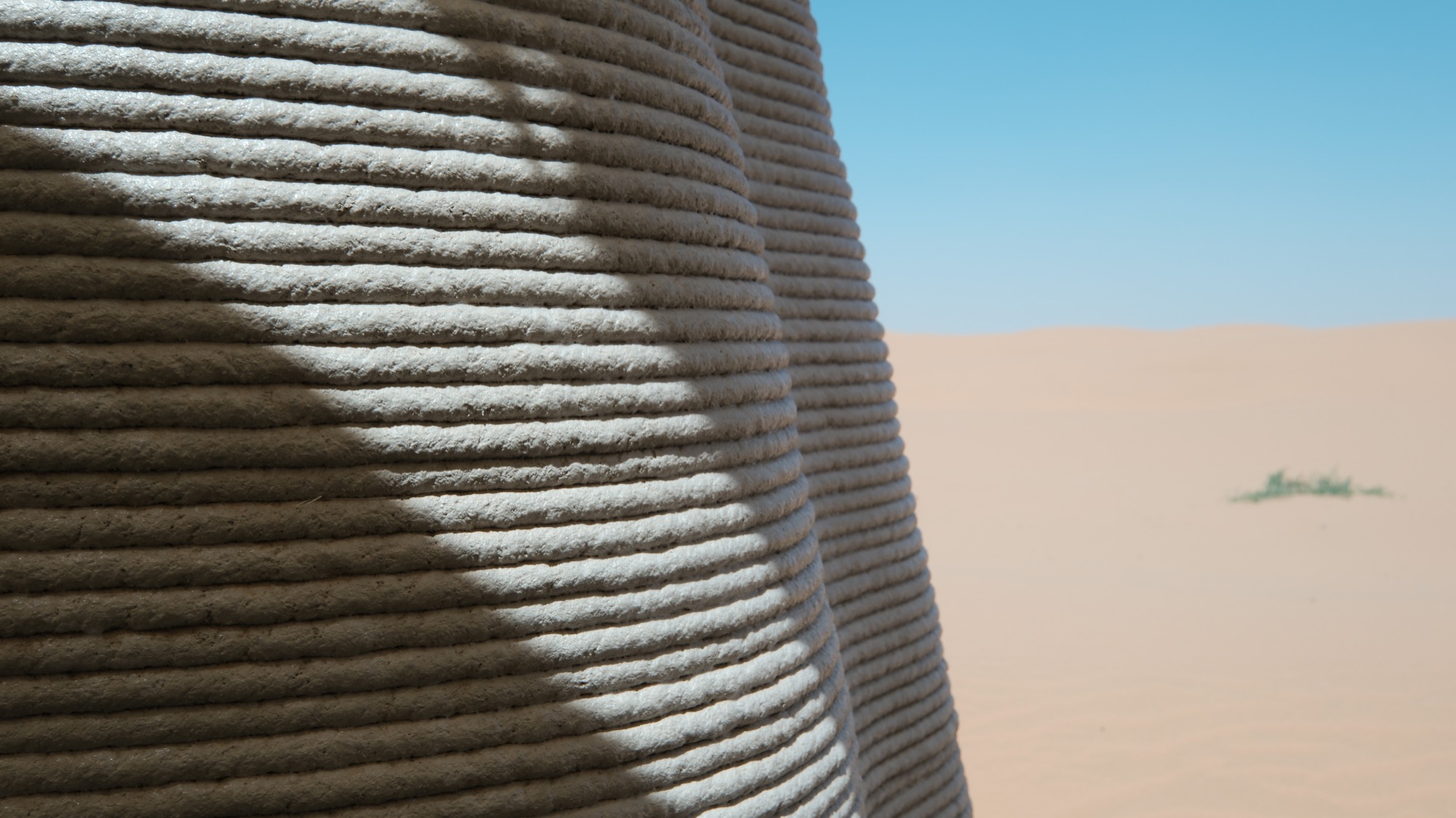

Each unit was prefabricated in Wuxi using the R3DCP printing system, with furniture embedded directly into the concrete body. The modules were transported by standard trucks and assembled on site in just two days, with the help of local herders.

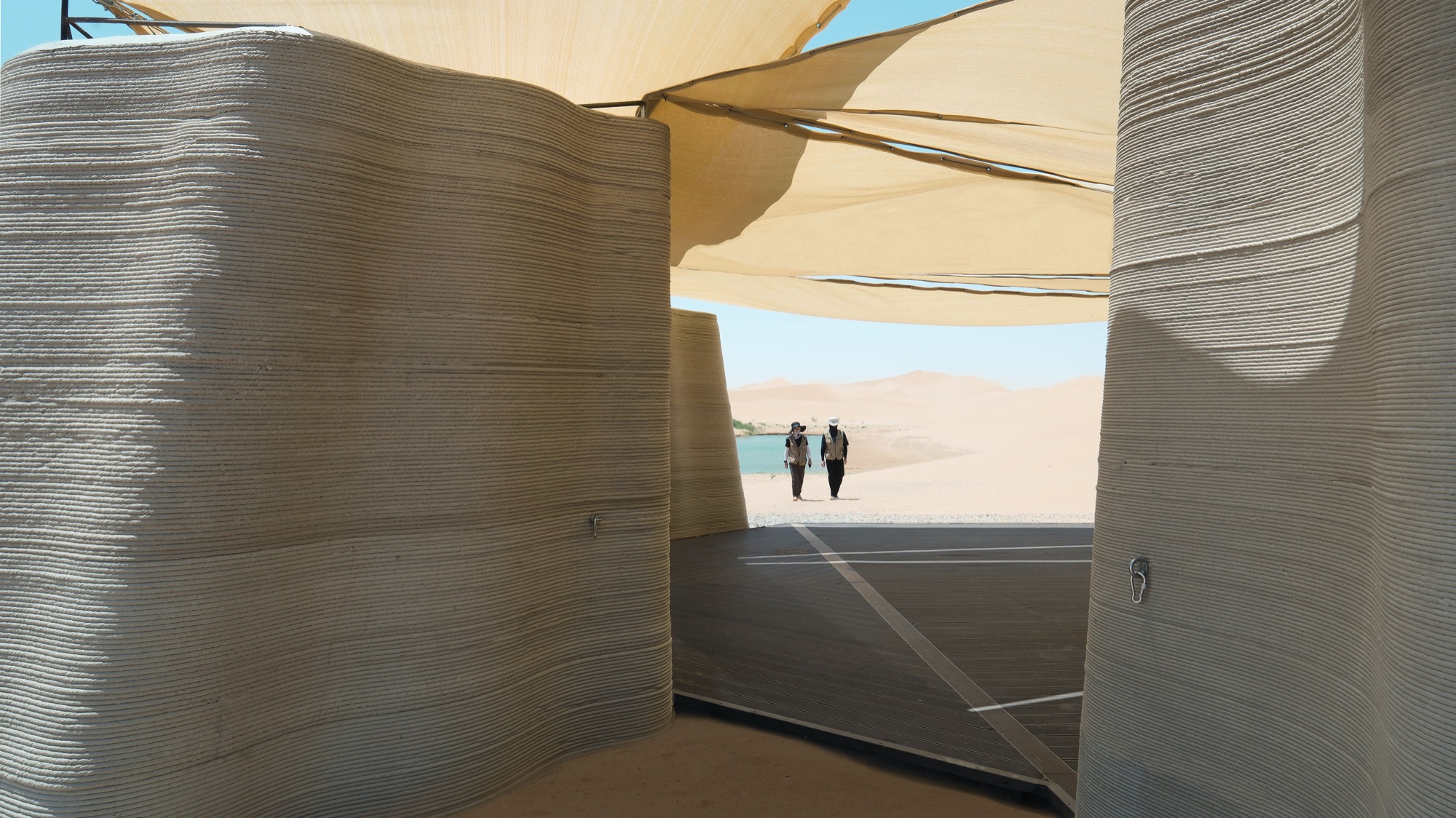

The undulating form of each unit mimics desert dunes, reducing wind load and blending into the topography. The 3D-printed concrete mix uses recycled desert sand, aligning construction with its environment. Each unit rests directly on the sand, stabilized by its own mass. Timber floors are raised on reused cargo pallets connected by steel pipes, allowing the cluster to be dismantled and relocated as the afforestation program expands.

Water is sourced from underground wells near the Helan Mountains and recycled through biological septic systems for irrigation. In summer, retractable shading mitigates heat gain, while in winter, Low-E glass and skylights admit sunlight and the hollow concrete walls retain warmth. The entire site runs on off-grid solar power, achieving zero carbon emissions and full energy independence.

The construction process includes prefabrication, transport, on-site assembly, and installation of life-support systems was streamlined to minimize environmental disturbance. No concrete was poured on site; no waste was left behind.

The Desert Noah Ark not only aids ecological recovery in Inner Mongolia but also demonstrates how 3D-printed architecture can sustain human life in extreme conditions. Amid the desert, humanity, technology, and nature converge to shape a new mode of existence, each printed wall and planted tree marking a commitment to the future.

More design detail

Editor

Anh Nguyên

Client

Alxa Tennger Desert Ecology Fund

Gross Area

150m2

Completed

2025

Photo

ATDEF team, Huaer Lin, Ziwen Hu, Yong Hu