Studio ThusThat has designed a new collection of furniture and interior items made from recycled aluminium off-cut ‘crusts’. The pieces are cut from a single sheet of salvaged aluminium sourced from a smelter, in such a way that every piece, every offcut, is used. The studio is also making the crust sheets available for architectural and interior design uses in a variety of formats.

In the early stages of aluminium production, smelters cast the molten metal into massive blocks weighing over 25 tonnes. These blocks are clad with undulating, organic textures that are the result of the casting process. In preparing the blocks to be sent to other factories for the production of aluminium cans, computers and cars, the sides are sawn off. Left behind are large thin plates with raw textured surfaces–these plates are colloquially known in the factory as the ‘crusts’.

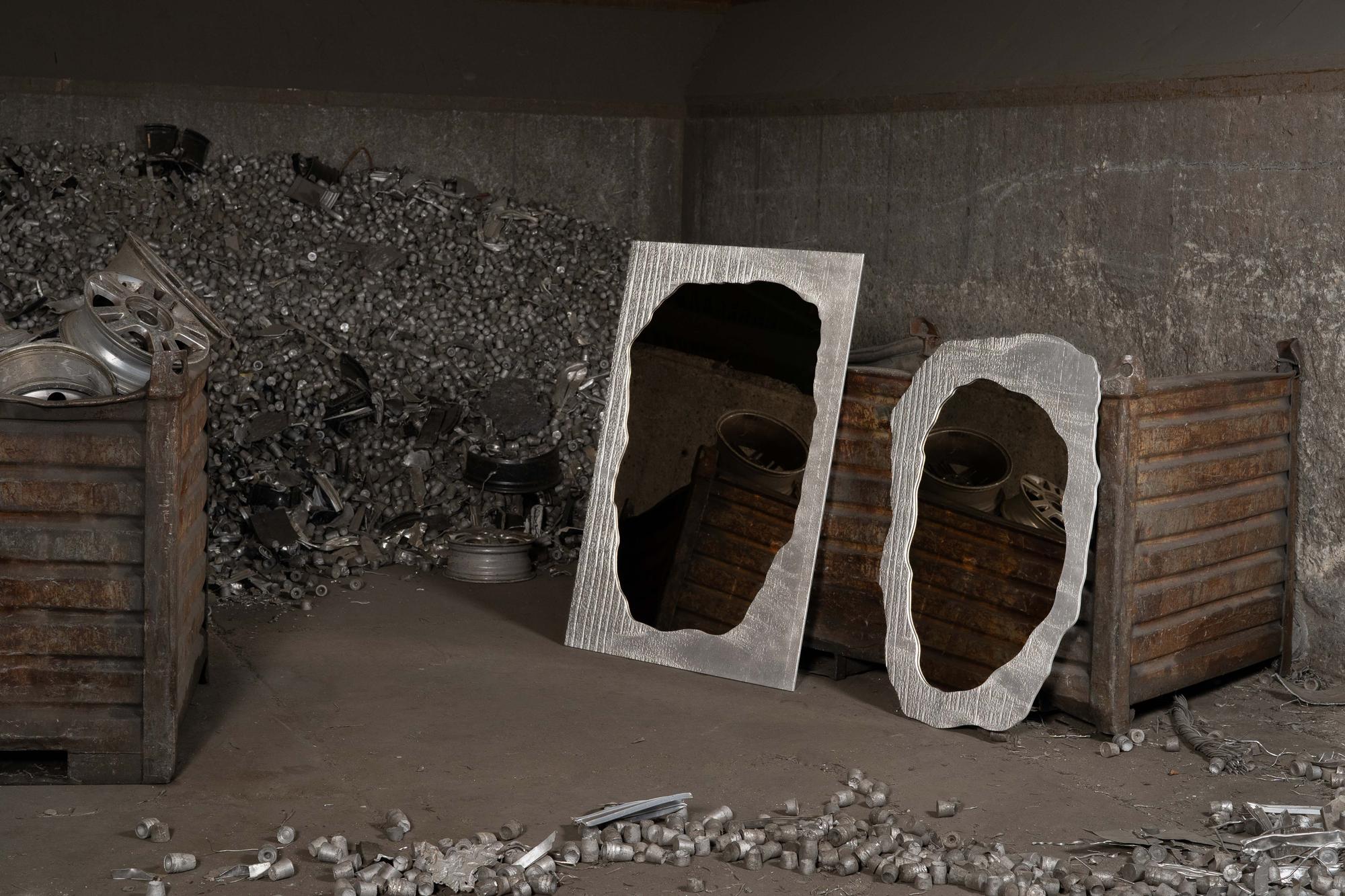

ThusThat, in a continuation of their exploration of industrial narratives, repurposes the aluminium crusts to create a series of interior objects that reflect the unexpectedly raw backstory to an everyday material. The edges are jagged and rough, resulting in rugged forms that seem to have been themselves byproducts of some brute industrial process. The backside of the plates still show traces of the giant factory saws from which they were cut, while the front reveals the metal’s molten origins. The pieces are designed to be easily packed, assembled, disassembled, and recycled.

The design of the collection resulted from the studio’s own challenges when cutting the material in such a way that minimized the leftovers. They wondered if it would be possible to utilize the same principle of reusing offcuts in the designs themselves, whereby the cut of one object informed the next object’s form, and ultimately the entirety of a sheet was used.

The result is a large adhoc puzzle of jagged cuts and an unusual composition of pieces that echo the brute and raw production of aluminium, a metal we take for granted as pristine. Their hope in doing so is to draw attention to the processes and origins behind everyday materials. As is typical of their work, ThusThat photographed the collection in a factory setting, this time at Hydro Aluminium’s casting plant in Drunen, Netherlands.

This latest collection marks a continuation of ThusThat’s previous work which explored various waste streams of the mining industry against the backdrop of increased material extraction. In one of their earlier projects for instance, they explored the aluminium industry through its mining waste, ‘red mud’, designing a series of ceramic pieces with the mine tailings.

The title of the collection, ‘One Side Sawn’, holds a double meaning. On the one hand, it hints to the industrial process which created the crusts, being sawn off of the large plates which are formally referred to as ‘six sides sawn plates’; in this collection, the pieces are made utilizing just one side of the large blocks. On the other hand, the collection also aims to reveal an obscured side to aluminium that escapes the public eye.

The studio hopes in these pieces to explore a different aesthetic expectation of ‘perfect’ materials like aluminium that acknowledges the costs and scale of their production, particularly when aluminium is touted to be the metal of the future. In an era of finite materials and energy crises, they believe that familiarizing ourselves with the aesthetics of secondary and rougher materials is important as it may one day become the norm.

Alongside the exhibition of the collection, ThusThat has also made the crust material available as a surface in a variety of custom and standard formats for use in architecture and interiors. The surfaces are recycled, and infinitely recyclable.